Whether you're starting a business for the first time, or you're expanding and haven't purchased pallet racking in awhile, one of the first questions you're likely to be asking yourself is how much is rack, anyway? It's a good question to ask without a simple answer. Pallet racking can be anything from one bay of storage to a highly-personalized storage system, so the cost of pallet rack is highly dependent on your use case. This article will hopefully shed light on what to expect to pay for racking and provide you some helpful tips to save more on your pallet rack in the long run.

How The Cost Of A Pallet Rack Is Calculated

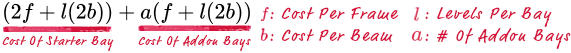

The cost for the simplest rack systems boils down to the cost of the main components; the uprights (or frames) and beams. Each bay will have two frames, and each bay will have two beams per number of levels. However, bays will share a frame with the bay before it in their row, which means that each "addon" bay after the "starter bay" in a row of racking only adds one frame to the total count. An equation for the cost of a basic row of racking would be:

Where f is the cost per frame, b is the cost per beam, lis the number of levels per bay, and a is the number of addon bays. However, the equation provided above doesn't cover everything that goes into a complete racking system. For instance, it ignores variation between bays and other costs associated with pallet racking including wire decking to provide additional support for your pallets, rack safety accessories like column protectors, aisle guards, and stop bars to protect your inventory and racking investment, or additional costs such as installation or permitting. It can be difficult to itemize how much everything might add up to at the end of the day, which is way our team at American Surplus is here to help you sort through every step of the process. We make it easy to visualize your racking system with free layout design services included with your quote, and we provide a simple, easy to understand quote with a breakdown of your material and labor costs.

How Much Do Rack Frames And Rack Beams Cost In 2025?

The global cost of steel is highly volatile; That combined with constant demand from new and growing businesses affects the price for pallet rack material like frames and beams on an ever-changing basis. Purchasing pallet rack from the manufacturer can feel like paying market price at the seafood counter, but a great way to save money and combat steel volatility is to seek out used pallet rack instead of buying new. Used pallet rack from a dealer like us can save you 40% or more off of the manufacturer MSRP while giving you access to the same high quality steel you'd get buying new.

Another cost you may not have considered is how long it will take to get your pallet rack. Time-wise, purchasing new pallet rack from the manufacturer can be very costly. When you buy new, your racking is oftentimes manufactured to order, leaving you waiting in line for months before your rack is even delivered. When you get in touch with our team at ASI, you're choosing immediate access to our 500,000 sqft. inventory as well as our nationwide dealer network. Shopping in-stock inventory at a dealer like ASI gives you a lead time measured in weeks, not months. Shorter lead times get your rack and business up and running faster.

How Can I Save Money On Pallet Rack?

No matter how you slice it, steel is expensive. But there are a few key ways you can save money when shopping for pallet rack:

1) Don't Buy More Rack Than You Need!

The cost of your rack scales with height, number of levels, and most importantly, capacity! The best way to keep costs down when shopping for pallet rack is to know how much inventory you're storing, and how much that inventory weighs. With your expected inventory in mind, you can make sure you aren't paying a premium for capacity you don't need.

2) Choose Used Racking!

One of the great things about material handling equipment is that it's almost never out of date; Good condition racking from 30 years ago is just as reliable as (and oftentimes even compatible with) racking manufactured this morning! Consistent manufacturing techniques, longstanding industry standardization, and specific safety regulations mean that the rack equipment landscape does not change much year to year. With no new features to miss out on, there are only upsides to choosing used racking. From shorter lead times to a net positive environmental impact through reuse to the massive savings that only scale with the size of your project. With per piece material costs over 40% lower than product direct from the manufacturer, you can quickly be looking at tens of thousands of dollars in savings on your racking system by partnering with a used rack dealer like American Surplus.

3) Consult With The Professionals!

The specifics of a material handling system can be difficult to tackle on your own. With over 30 years of experience under our belt designing storage systems for thousands of businesses across America, we know a thing or two about building the right storage solution for your needs on a budget that helps your business thrive. Our team can identify the most cost-effective storage solution for your business and help you put storage best-practices to work for you. With a simple, free consultation just a phone call away, you have nothing to lose by starting with the pros at American Surplus!